Design Considerations of ASD Systems

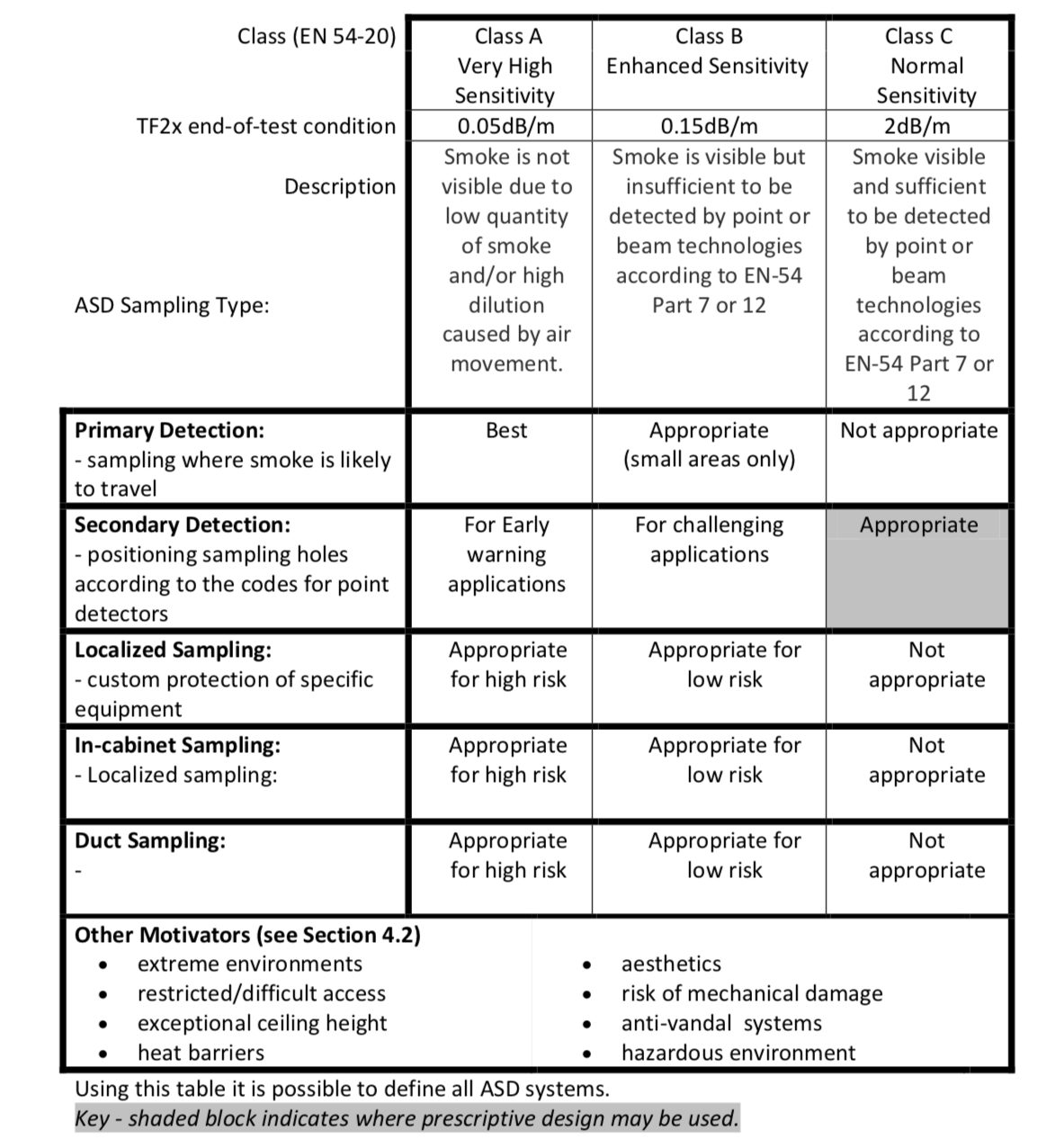

There are many reasons for using ASD systems. The detection sensitivity of such systems is frequently tailored to the particular application to achieve the performance capability desired without being susceptible to unwanted alarms.This section describes a means to define any ASD system encompassing all the essential elements in such a way that any individual system can be described in a single unambiguous phrase. The definition takes into account:

- Class of the detector (as defined in EN 54-20)

- Type or method of sampling (e.g. primary or secondary sampling)

- Compliance route (either prescriptive or performance based)

- Prime motivators for using an ASD system

Sensitivity Classes:

ASD Sampling Types/methods

Primary sampling

In-cabinet sampling

For In-cabinet Sampling, the pipework and air sampling points are arranged to monitor specific pieces of equipment and is distinct from the use of Localized Sampling systems in that the protected volume is small, generally self contained and has some distinct challenges and risk associated with the cooling of critical electronic and electrical equipment. Specific performance tests for such systems are given in this document (See 10.3) and it is generally considered that enhanced Class B or very high sensitivity Class A systems are appropriate to meet these performance tests.Duct sampling

In some cases the ASD can be arranged to sample from within a duct. There are two basic applications for such an approach:- Duct Smoke Detection (DSD) provided to trigger a control system to prevent smoke being transferred through a building;

- Duct sampling applications, where the detection of smoke in a duct is used to provide early warning of fire in the area (or equipment) from which the air is being extracted.

In either case, earlier warning using a higher sensitivity detector is possible using an ASD system and is often cited as a reason for using an ASD system as an alternative to passive type duct detectors.

ASD systems can be used for DSD installations dependant on the risk and application. They do not rely on the duct air-flow to pass any smoke samples through the detector because of the integral aspirator or fan.

Note: See the FIA Code of Practice for Duct Smoke Detector (DSD) systems for further information In areas that are less than 100m2 (e.g. detention cells) duct sampling may be at a similar smoke

sensitivity to replace point smoke detectors i.e. ~4.0%obscuration/m.

In larger areas the smoke sensitivity would have to be increased to cater for either the increased duct airflow or the larger risk area. Manufacturer’s recommendations should be sought to determine the optimum position in the duct for the intake and exhaust pipes and the maximum duct airspeeds (See 10.7 for specific application guidance).

When used in a duct sampling application, the maximum floor area covered by one duct mounted ASD should not exceed 2000m2 or one smoke detection zone under BS 5839-1: 2010 Section 2:13.

Note: When an ASD is used in a duct sampling application to provide early warning of a fire condition the area protected should also be monitored by secondary detection to provide protection in the event of the duct airflow shutting down.

Route to Compliance (Prescriptive or Performance Based)

The decision as to whether performance tests should be conducted during commissioning depends on the classification of the ASD system being deployed. Generally, there is only one situation where a performance test can be omitted and that is when; an approved ASD system is deployed (and is fully compliant with the specific requirements of the product approval), with sampling hole spacing that falls within the full requirements of the relevant prescriptive code (e.g. BS 5839-1: 2008),. This situation is highlighted in the table on page 19. In all other situations it is recommended that a suitable performance test is specified and carried out during commissioning to verify the system. Refer to Section 14.

Common Motivators

There are many motivations for deploying an ASD system. The following list is intended to assist in the classification and therefore specification of ASD systems.- Extreme environments

Harsh environments (e.g. extreme temperature, humidity, contamination etc.). - Restricted/difficult access

Future access for maintenance will be difficult or even impossible after installation. - Exceptional ceiling heights & heat barriers

Stratification, dispersion and dilution issues are present as well as access restrictions. - Aesthetics

Architectural or aesthetic requirements preclude mounting services on the ceiling. - Risk of mechanical damage

Operational damage is anticipated (e.g. in racking and storage systems). - Anti-vandal systems

Vandalism may be an issue so therefore discreet detection is required. - Hazardous environments

The risk is hazardous e.g. explosive, chemical, radioactive environments etc.

Primary Detection Sampling Systems

Are usually arranged to monitor the flow of air movement by the use of pipework and air sampling points mounted directly in the airflow. This type of system is usually regarded as supplementary to other forms of detection due to its limited response capability once the air movement ceases.In such a system when monitoring a single point of supply or extract, its system sensitivity may be directly related as equal to the sensitivity of the central detector due to the cumulative effect. In the case of a system monitoring more than one point of supply / extract then the system sensitivity will only be determined in discussions with the manufacturer or his representative.

Always locate the sampling points in a position to which smoke may reasonably be expected to travel. This may sound obvious, but, for example, do not expect ceiling mounted sampling points to operate satisfactorily if air flow prevents the cool smoke from an incipient fire from reaching ceiling level. In this instance it is usually better to locate the sampling pipes directly in the airflow (for example in an air conditioning unit air intake). There is no substitute for carrying out smoke tests prior to installation of pipes to indicate suitable sampling point location.

Secondary Detection Sampling Systems

Are arranged such that the air sampling points are sited and spaced as if they are point type smoke detectors. They can be positioned to satisfy NFPA 72, NFPA 76, BS 5839-1, BS 6266 and local fire code requirements when the calculated relative sensitivity per air sampling hole equates to a point detector. See Relative Sensitivity below.Maximum Permissible Transport Time

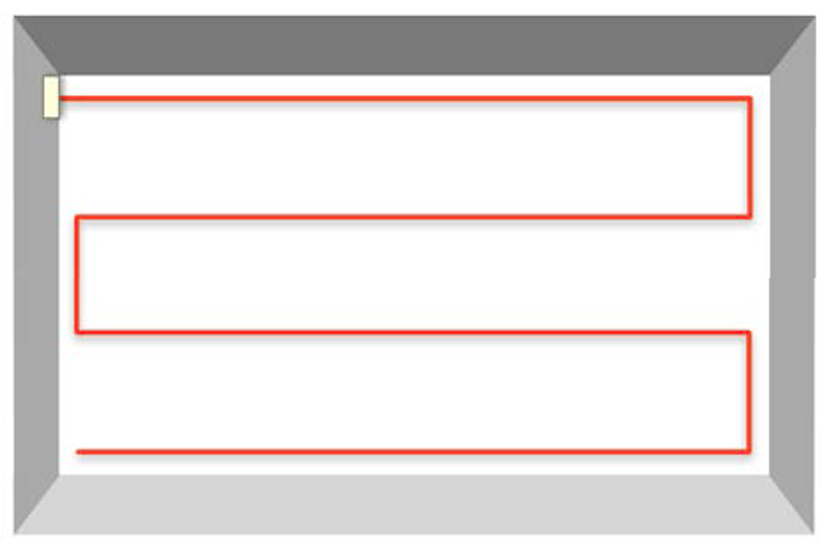

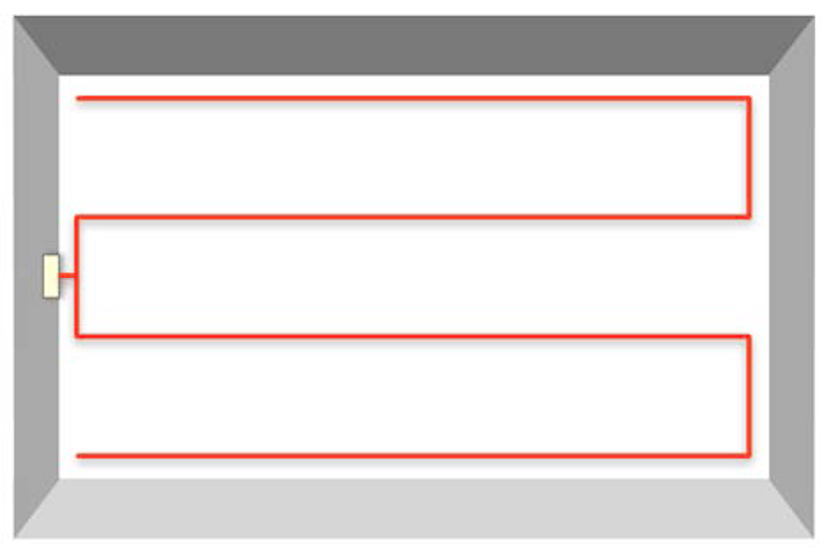

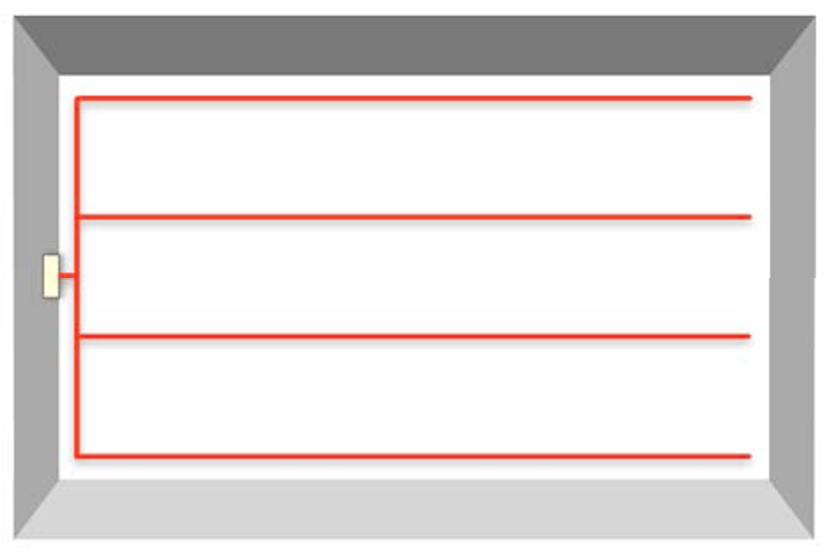

The time taken for a system to transport a sample from a protected area should not exceed 120 seconds (2 minutes). Transport times in excess of this must be the subject of a variation. Shorter maximum transport times may be desirable in certain applications and should be specified as part of the risk assessment. For example, Class A ASD systems are generally designed with transport times of less than 60 seconds.Maximum transport time can be directly affected by the installed sample pipe design, see the following Figures. The 4-branch design will provide the shortest transport time.

Single branch system

Balance

Relative sensitivity

Recommendations:

The design methodology for the ASD system should be understood and in full accordance with the manufacturer’s instruction and approval requirements.

Open-ended pipe systems (with no end cap whatsoever) are not recommended. The maximum transport time should not exceed 120 seconds (2 minutes).

The relative sensitivity of each sampling point should be better than 5%/m unless otherwise stated in the manufacturers documentation.

Where possible the predicted performance of a sampling network should be compared with the measured performance on site in order to confirm that the pipe-work is installed as intended.

Normal Environments

ASD systems are increasingly being used in “normal” environments on account of the benefits of concealed sampling holes, centralized maintenance and/or the cumulative effect.

10.1.1 Where an ASD is used to protect a number of separate areas/rooms, it is good practice to provide at least two sampling holes for each area/room, wherever possible. This is to reduce the possibility of a decrease in sensitivity due to a partially or fully blocked sampling hole. The use of two sampling holes per area/room will ensure that the benefits of the cumulative effect are present to provide more reliable detection.

10.1.2 While addressable point detection can indicate the location of the individual area/room, an ASD (used to protect a number of separate areas/rooms) may not be able to provide such information (see 10.1.3). However, when investigating an alarm, the extra time provided by a Class A or Class B ASD system may compensate for the lack of addressability. Furthermore, a Class C alarm is likely to be readily apparent on investigation, particularly where the number of areas/rooms is not excessive and each is readily accessible (e.g. <10 rooms with unlocked or "windowed" doors). However, the important factor when determining the number of separate areas/rooms that can be covered is the time it takes to reach them and inspect them. Search distances are specified in some codes for non-addressable systems but the following recommendations are also provided in terms of search times.

10.1.2.1 It should be possible to investigate all individual areas covered by a Class C ASD within 1 minute of arriving at the zone and by travelling less than 60m.

10.1.2.2 Where the ASD system is arranged to provide a Class B pre-alarm signal and it is possible to investigate all individual areas covered by an ASD within 2 minutes of arriving at the Zone and by travelling less than 60m.

10.1.2.3 Where the ASD system is arranged to provide a Class A pre-alarm signal and it is possible to investigate all individual areas covered by an ASD within 5 minutes of arriving at the Zone and by travelling less than 60m.

Note: The 60m travel distance limit above match clause 13.2.3 of BS 5839-1:2008 for non- addressable automatic fire detectors.

10.1.3 Some multi-channel ASD systems can identify the channel (or pipe) into which smoke is drawn and so provide a more precise indication of the likely location of the fire within the zone. Where such capability is available, the recommendations given in 10.1.2 applies to each individual sub-zone that can be identified.

Further information regarding the design of AVA Aspirating Smoke Detection Systems